News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Industry News

Internal cathodic protection of seawater cooled power plant condensers

- Author:Libo

- Source:wwww.anchorwestinsurance.com

- Date:2021-06-11

- Click:0

Internal cathodic protection of seawater cooled power plant condensers

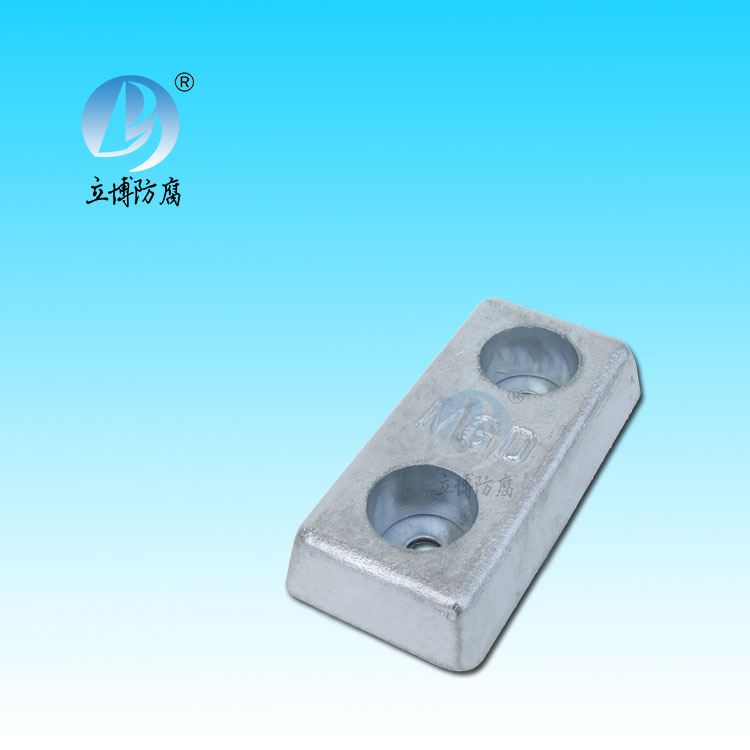

Forced current internal cathodic protection for seawater cooled condensers in power plants is a new technology being developed in recent years. The following is an application example of internal cathodic protection for large condensers with copper and aluminum alloy tubes. This is a one-way road with no branches; Tube bundle heat exchanger with box manifold; Each plant needs two such condensers; The surface area of the steel box type main pipe with anti-corrosion layer to be protected is 65m2; The total surface area of pipeline, population and export site is 20m2; Cooling water of 30~40℃ flows through the condenser at a rate of about 2m· S ˉ1. Cathodic protection is needed not only for the corrosion protection of the steel box-type pipe, but also to prevent bimetallic corrosion between steel and copper and aluminum pipe materials.

In addition, the solid content of cooling water is high, the flow rate is fast, and the continuous damage of the surface film constitutes a serious anti-corrosion condition. It is not enough to implement cathodic protection alone. Additional measures are needed to promote the formation of surface films. This is possible with an iron anode because the hydrated iron oxide produced by the anode promotes the formation of a copper surface mask.

Each condenser needs six iron anodes for corrosion protection, and each anode weighs 13kg. There are 14 rod-like iron and titanium anodes in each exit chamber, 5μm thick and 0.73g in mass. The mass loss rate of these iron anodes is 10kg·Aˉ1 ·Aˉ1. The protective current density of the inner surface of the coated cooler is 0.1a ·mˉ2, and that of the copper alloy tube is 1A·mˉ2, which corresponds to A protective current of 27A. A transformer with an automatic potential control capacity of 125A/10V is installed for each main condenser, and a fixed zinc reference electrode is used for potential control and monitoring. Figure 21-1 shows the anode arrangement in the entrance chamber.

客服QQ

客服QQ