News

News

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Q & A

What are the corrosive and protective measures for metals

- Author:Libo

- Source:wwww.anchorwestinsurance.com

- Date:2021-06-11

- Click:0

Sacrificial anode method a method of polarizing the protected body to reduce the rate by connecting the protected metal to a metal and alloy (the sacrificial anode) that can provide cathodic protection current. In the earth battery formed by the protected metal and the anode, the protected metal body is the cathode, and the potential of the sacrificial anode is often negative to the potential of the protected metal body. In the protective battery, the anode is eroded and consumed, so it is called the "sacrificial" anode.

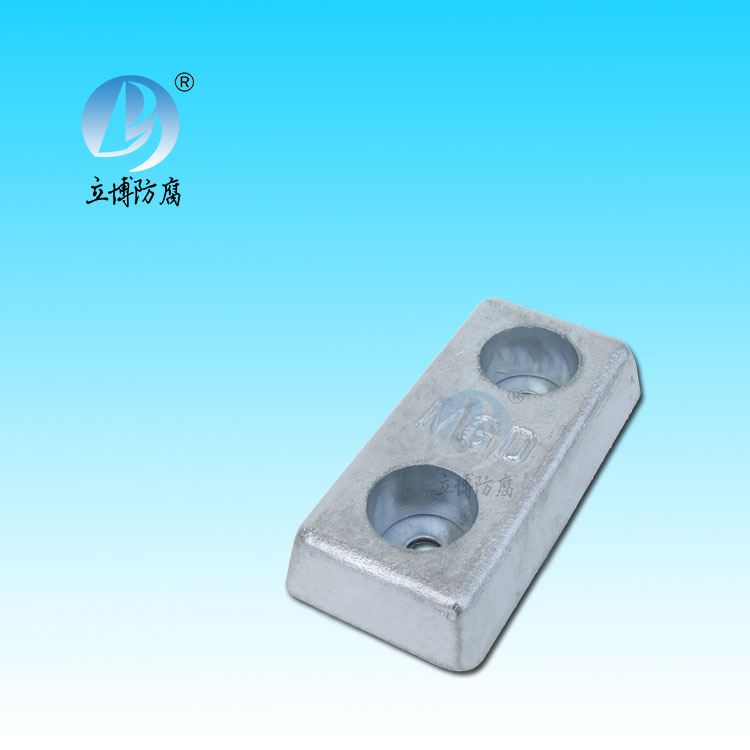

The materials commonly used as sacrificial anodes are magnesium and magnesium alloys, zinc alloys, aluminum alloys, etc. Magnesium anode is used in fresh water and soil with high resistivity, zinc anode is mostly used in soil with low resistivity and sea water, aluminum anode is mainly used in sea water, sea mud and crude oil storage tank sewage media.

The main characteristics of sacrificial anode protection are :(1) a wide range of use, especially for medium and short intervals and complex pipe networks; (2) the anode output current is small, and the possibility of cathode stripping is small; (3) the construction work is small when it is constructed together with the pipeline installation; (4) the maintenance work is simple during operation. (5) the anode output current can not be adjusted, and the controllability is small. 2. Forced current protection A method by which the protected metal is connected to the negative electrode of the impressed current and the protection current is provided by an external power source to reduce the erosion rate. The external power supply will introduce the protection current into the ground through the buried auxiliary anode, and provide the protected metal through the soil. The protected metal is still the cathode in the earth battery, and only the reduction reaction occurs on its surface, and the oxidation reaction of metal ions will not occur again, so that the erosion is inhibited. Forced current protection of the main equipment, potentiostat, auxiliary anode, reference electrode.

The main features of the forced current protection law are :(1) it is used for the protection of long distance pipelines and regional pipe networks; (2) the output current is large, and the one-time investment is relatively small; (3) the installation work is small, and the old pipelines can be supplemented with cathodic protection; (4) it needs professional staff to maintain during operation; (5) it is easy to realize remote automatic monitoring. Components of forced current cathodic protection System · Anodic ground bed The anodic ground bed is generally divided into shallow buried anodic ground bed and deep well anodic ground bed.

,

Cathodic protection control system The control system of cathodic protection is composed of potentiostat, control box, anode ground bed and cathode current point. The anode ground bed is connected to the anode contact of the potentiostat by a bus-cable. Two cathode cables and two long-life solid copper sulfate reference electrodes for potential control are provided at the cathode galvanization point.

· Cathodic protection testing system The cathodic protection testing system is composed of a potentiostat and a pipeline test pile. The potentiostat can automatically measure the potential of the energized point, the working potential and output current of the potentiostat; The pipeline test pile can detect the protection potential of the pipeline and the working potential, output current and open circuit potential of the sacrificial anode.

· Discharge protection shall be adopted for pipes in areas with strong stray current interference in the discharge system of cathodic protection. The discharge anode group must be set according to the influence of stray current in the parallel section between long distance pipeline and high voltage transmission line or the parallel section crossing with electrified railway. · Temporary Protection System According to the requirements of the design code for cathodic protection, if the construction period of the pipeline exceeds 6 months, the pipeline shall be equipped with a temporary cathodic protection system to avoid soil erosion before the applied current cathodic protection system is put into use.

,

Insulation and electrical connection system for cathodic protection In order to ensure that the cathodic protection current does not leak to the unprotected metal sector, insulation joints are set up at both ends of the long distance transmission pipeline.

· Cathodic protection of pipes in bushing When pipes cross roads or railways, steel bushing is required. In order to ensure that the pipe in the casing is not corroded during the designed life, it is necessary to use bracelet type zinc anode or zinc band pole for cathodic protection.

客服QQ

客服QQ