News

News

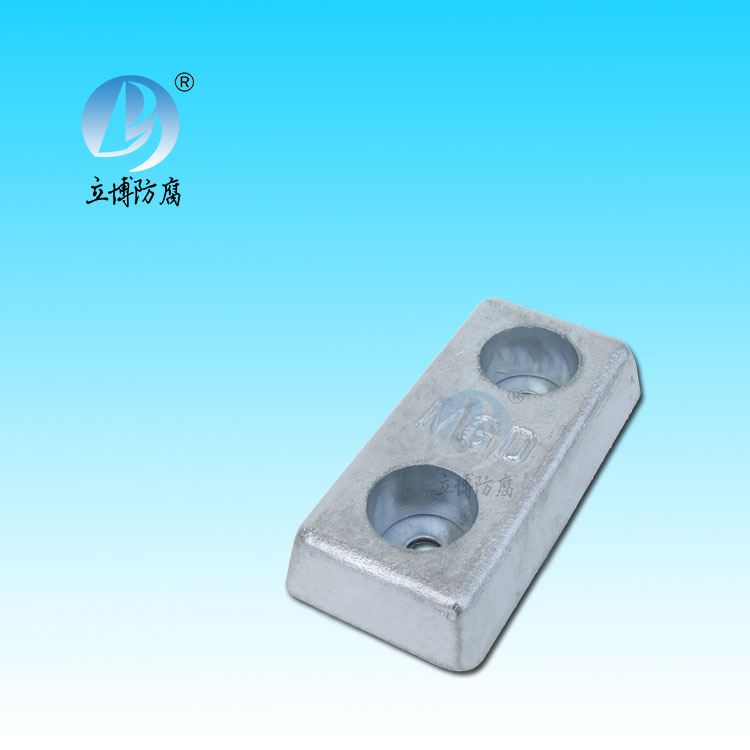

- What is a sacrificial anode

- Basic requirements for reference...

- What does the reference electrode do...

- Why are zinc blocks attached to the ...

- What is the principle of impressed...

- What material does metal structure...

Contact

Phone:18739187123

hotline:0391-7588881

E-mail:970512272@qq.com

Address:Wuzhi County, Jiaozuo City, China

Q & A

How is the effect of heat shrinkable duct anticorrosive tape?

- Author:Libo

- Source:wwww.anchorwestinsurance.com

- Date:2021-08-16

- Click:0

The thermal shrinkage belt of pipeline anticorrosion is applied to hankou anticorrosion of oil and natural gas pipe for long-distance transportation in the oil and natural gas industry. It is widely used in the fields of welding corrosion of long distance oil and natural gas steel pipes, joint corrosion corrosion of urban gas pipe network, joint corrosion corrosion of heating steel pipes, joint corrosion corrosion of water pipe from water pipe and so on. Pipeline anti-corrosion thermal shrinkage belt is characterized by high mechanical strength, strong aging resistance and good environmental stress resistance. Excellent bonding performance, easy to use. Maximum operating temperature 80℃, applicable to external anticorrosive coating PE/FBE/PP. Steel tube preheating temperature 75℃.

Anticorrosive heat shrink belt of steel tube anticorrosive pipe is a new kind of anticorrosive material for welding of steel tube with good performance and simple operation, which is composed of double layer material of base material and hot melt adhesive layer. The substrate is plastic sleeve formed by extrusion, radiation crosslinking and stretching of polyethylene raw material. Hot melt adhesive is a special adhesive, solid at room temperature, heated melting state can flow, can be coated on the substrate, have good adhesion to metal and plastic. The outer anticorrosive layer of the steel pipe is usually three-layer structure. The anticorrosive material primer is in contact with the steel pipe, the middle is hot melt adhesive, and the outermost layer is crosslinked polyethylene.

客服QQ

客服QQ